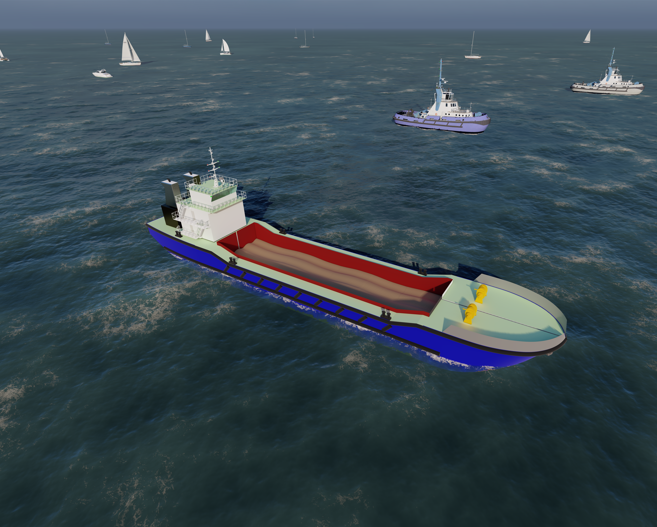

A Split Hopper Barge is a specialized marine vessel designed for transporting and disposing of dredged materials such as sand, gravel, and mud. Widely used in port construction, land reclamation, and coastal maintenance projects, these barges are built for durability, high efficiency, and safe operations in challenging marine environments.

Split Hopper Barges are typically constructed with a robust steel hull that can withstand heavy loads and harsh marine conditions. The hull is split lengthwise into two halves, which open from the center to discharge the cargo directly into the water. This innovative design ensures quick unloading without the need for additional machinery.

These barges come in various capacities, ranging from small units of 500 cubic meters to large-scale vessels exceeding 3,000 cubic meters. The size and load capacity can be customized based on project requirements, ensuring optimal performance for different dredging operations.

The primary advantage of a Split Hopper Barge is its fast and efficient unloading system. With its split-hull mechanism, the vessel can discharge dredged materials in seconds, significantly reducing turnaround time. Additionally, these barges are self-propelled or tug-assisted, offering flexibility in different operational scenarios.

Split Hopper Barges play a critical role in dredging projects, offshore construction, port deepening, coastal protection, and beach nourishment. Their ability to transport large volumes of material quickly makes them essential for keeping waterways navigable and supporting large-scale marine engineering works.

Modern Split Hopper Barges are equipped with advanced safety systems, including anti-heeling mechanisms, GPS navigation, and automated control panels. Regular maintenance of the hull, hydraulics, and engines ensures long-term operational reliability and compliance with international maritime safety standards.

Whether for dredging, reclamation, or coastal defense projects, the Split Hopper Barge remains a vital tool in the maritime industry. Its unique design, high load capacity, and rapid unloading capabilities make it indispensable for efficient and cost-effective marine operations.